In today’s fast-evolving power distribution environment, utilities and EPC contractors require cable systems that deliver both electrical reliability and mechanical protection. Concentric cable has become a preferred solution for underground and low-voltage distribution networks because of its enhanced safety, stable electrical performance, and simplified installation.

As a global manufacturer of overhead conductors and power cables, HNBF Power supplies utility-grade concentric cable solutions designed to support long-term grid reliability, harsh environmental conditions, and demanding installation requirements.

This guide explains how concentric cables work, where they are used, and how engineers and procurement teams can select the right design for their projects.

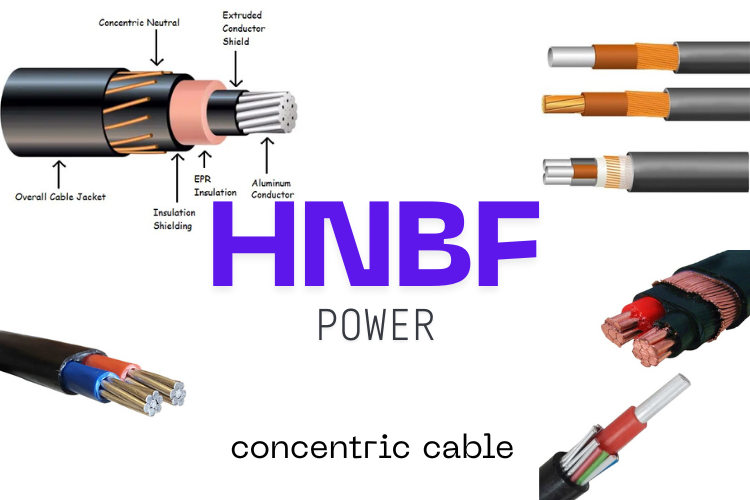

What Is a Concentric Cable?

A concentric cable is a power cable design in which the phase conductor is surrounded by one or more layers of concentric neutral or grounding conductors. These neutral wires are helically applied around the insulated core, forming a symmetrical structure.

This construction is commonly referred to as:

-

concentric neutral cable

-

concentric conductor cable

-

concentric grounded power cable

The concentric layer serves as both a neutral return path and a protective conductor, helping improve electrical balance and fault performance.

Key Construction of Concentric Cable

Central Phase Conductor

The core conductor is typically:

-

aluminum or copper

-

compacted or stranded for flexibility

-

designed for stable current carrying capacity

HNBF Power manufactures concentric cable with carefully selected conductor materials to meet international power distribution standards.

Insulation System

The phase conductor is insulated using materials such as:

-

XLPE

-

PVC

These materials offer high dielectric strength, thermal resistance, and long operational life in underground or buried installations.

Concentric Neutral Layer

The concentric layer consists of evenly spaced neutral wires applied around the insulation. This symmetrical geometry provides:

-

balanced electromagnetic fields

-

controlled fault current paths

-

improved grounding performance

Outer Jacket

An outer sheath protects the entire assembly from:

-

moisture ingress

-

soil chemicals

-

abrasion and installation stress

Why Utilities Prefer Concentric Cable

Improved System Safety

One of the main reasons concentric cable is widely used in low-voltage and secondary distribution networks is its inherent grounding capability. The concentric neutral conductors provide a continuous and reliable earth path around the cable.

This significantly reduces the risk of:

-

dangerous touch voltages

-

uneven grounding

-

unstable neutral return

Stable Electrical Performance

Because the neutral conductors surround the phase conductor evenly, concentric cables offer:

-

better electromagnetic field balance

-

reduced inductive interference

-

more predictable impedance characteristics

For urban distribution networks and compact underground systems, this design helps maintain consistent voltage quality.

Simplified Installation and Layout

Concentric cables allow utilities to avoid installing separate grounding conductors. This simplifies:

-

trench design

-

jointing operations

-

termination layouts

For EPC contractors managing tight project schedules, concentric cable improves installation efficiency without compromising safety.

Typical Applications of Concentric Cable

Concentric cable is widely applied in:

-

underground low-voltage distribution networks

-

residential and commercial service connections

-

utility secondary networks

-

renewable energy distribution systems

-

industrial power supply corridors

It is particularly suitable for urban infrastructure projects where mechanical protection and grounding integrity are critical.

Concentric Cable vs. Standard Power Cable

Electrical Grounding Capability

Unlike standard single-core power cables, concentric cable integrates the neutral and grounding conductors directly into its structure. This design eliminates dependence on external earth conductors.

Mechanical Protection

The surrounding neutral wires act as an additional protective layer, improving resistance to mechanical impact during installation and backfilling.

Fault Current Performance

In fault conditions, the concentric layer distributes return current more evenly, helping reduce localized overheating and enhancing system reliability.

How HNBF Power Designs Utility-Grade Concentric Cable

HNBF Power combines advanced conductor stranding technology with strict quality control to deliver stable, utility-approved concentric cable systems for global markets.

Our production portfolio supports:

-

aluminum concentric cables

-

copper concentric cables

-

customized conductor cross-sections

-

tailored insulation and jacket materials

As a global supplier of AAC, AAAC, ACSR, ABC cables, LV power cables, and concentric cables, HNBF Power ensures full compatibility between overhead and underground distribution solutions for integrated grid projects.

Our engineering team supports project-specific requirements, including:

-

short-circuit current design

-

soil and environmental conditions

-

regional installation standards

-

utility technical specifications

Selection Factors for Engineers and Procurement Teams

Conductor Material

The choice between copper and aluminum affects:

-

conductivity

-

mechanical strength

-

installation weight

-

project budget

Aluminum concentric cable is often preferred for utility distribution projects due to its cost efficiency and lighter handling.

Neutral Conductor Size

The total cross-section of the concentric neutral wires must be selected based on:

-

expected neutral current

-

fault current requirements

-

grounding design criteria

Insulation and Jacket Performance

Environmental exposure, soil moisture, and chemical conditions determine whether XLPE or PVC insulation and specific jacket compounds should be used.

Working with an experienced manufacturer like HNBF Power helps ensure the cable design fully complies with local utility standards and project specifications.

FAQs About Concentric Cable

What is the main purpose of the concentric neutral layer?

The concentric neutral layer provides a continuous return and grounding path, improving electrical safety and fault current handling in power distribution systems.

Is concentric cable suitable for underground installations?

Yes. Concentric cable is widely used for underground and buried installations due to its mechanical protection, balanced electrical structure, and reliable grounding performance.

Can concentric cable be manufactured with aluminum conductors?

Absolutely. Aluminum concentric cable is commonly used in utility networks because it offers good conductivity, lower weight, and optimized project costs.

How is concentric cable different from ABC cable?

ABC cable is designed mainly for overhead low-voltage distribution, while concentric cable is typically designed for underground and secondary network installations with integrated grounding.

Power Your Distribution Projects with HNBF Power

Choosing the right concentric cable is critical for long-term grid reliability, operational safety, and installation efficiency. With advanced manufacturing capabilities, global project experience, and a complete portfolio of overhead and underground power cables, HNBF Power delivers dependable concentric cable solutions for utilities, EPC contractors, and infrastructure developers worldwide.

Contact HNBF Power today to discuss your project requirements and receive customized concentric cable solutions engineered for your distribution network.