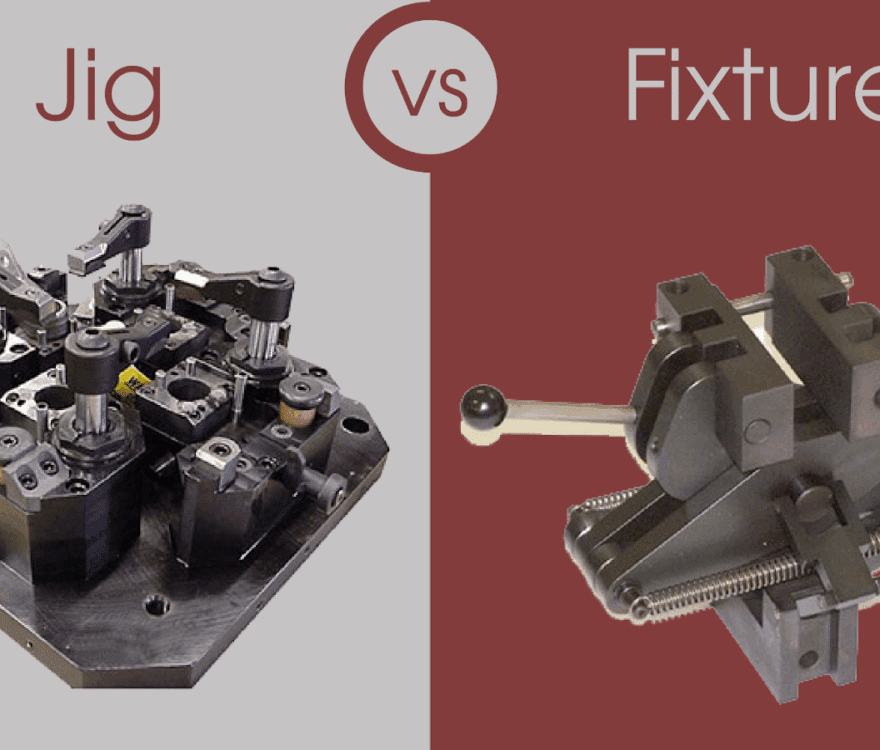

CNC machining efficiency is not achieved solely through advanced machines or skilled operators; it begins with how the workpiece is held and supported. Jig and fixture design establishes a stable and repeatable foundation that allows machines to cut precisely, maintain tolerances, and reduce setup errors. Properly engineered fixtures ensure that every part begins in the correct position, resists deflection under cutting forces, and allows operators to execute programs with confidence. In modern manufacturing, focusing on efficient workholding is critical for reducing cycle times, improving part quality, and enhancing overall production reliability.

As manufacturing demands grow, parts become more complex, tolerances tighter, and delivery timelines shorter. Generic setups or improvised fixtures are no longer sufficient to meet these challenges. Jigs and fixtures tooling provides repeatable support and precise alignment that translate directly into measurable efficiency gains. Using specialized jig and fixture design devices, CNC shops can maintain consistent output, reduce scrap, and improve workflow continuity, creating a foundation for long-term production success.

The Impact of Jig and Fixture Design on CNC Efficiency

Improving Accuracy Through Controlled Positioning

CNC machines rely on the accurate placement of workpieces relative to machine axes. Fixtures define these reference points, ensuring that programmed tool paths align with the intended design. Properly designed jigs prevent movement, eliminate reliance on manual adjustments, and maintain dimensional integrity across multiple parts. By creating repeatable positioning, these fixtures allow high-volume production without sacrificing precision.

Minimizing Workpiece Deflection and Vibration

Machining generates cutting forces that can deform or shift a part if it is not properly supported. Jig and fixture design devices counteract these forces with strategically placed supports and balanced clamping, reducing vibration and chatter. Stable workholding protects tools, improves surface finish, and ensures consistency across production runs. By controlling how parts react to cutting forces, fixtures directly improve efficiency and reduce the risk of costly rework.

Key Principles of Effective Jig and Fixture Design

Datum Selection and Locating Strategy

A successful fixture starts with proper datum selection. Datums act as reference points for machining and ensure that critical features maintain their intended spatial relationships. Effective jig and fixture design constrains only the necessary degrees of freedom, avoiding over-constraint that can introduce stress or distortion. This approach guarantees consistent part positioning and supports precision across all operations.

Clamping Solutions That Maintain Part Integrity

Clamping must secure the workpiece without deforming it. Excessive force can distort thin-walled or complex parts, causing errors after machining. Advanced jigs and fixtures tooling distributes pressure evenly and applies force where the part is strongest. Controlled clamping preserves geometry, maintains tolerance accuracy, and reduces scrap, supporting reliable and efficient CNC production.

Enhancing Productivity with Jigs and Fixtures Tooling

Reducing Setup Time and Operator Dependency

Manual alignment and repeated measurement slow production and introduce variation. Fixtures simplify setup by guiding operators to load parts in consistent positions, enabling faster changeovers. Reduced setup time increases machine utilization and allows operators to focus on monitoring machining rather than correcting misaligned parts, improving workflow efficiency.

Standardizing Processes Across Operators

Fixtures create repeatable conditions that make processes less dependent on operator skill. Clear locating features and intuitive clamping mechanisms ensure consistency between shifts. Standardized setups reduce training requirements, enhance process reliability, and allow CNC shops to scale operations without compromising quality or efficiency.

Custom Jig and Fixture Design for Complex CNC Parts

Tailoring Support for Geometric Complexity

Standard fixtures may be insufficient for intricate or high-precision components. Custom jig and fixture design allows engineers to adapt locators, supports, and clamps to the specific part geometry. Tailored fixtures provide stability where it is needed most, while maintaining access for cutting tools and inspection, ensuring accuracy even on challenging components.

Supporting Multi-Operation Machining

Many CNC parts require several operations across multiple machines. Custom fixtures maintain consistent datums throughout the workflow, preventing tolerance stack-up and alignment errors. By preserving reference points from one operation to the next, these fixtures reduce rework, improve assembly fit, and streamline overall production efficiency.

Common Challenges in Jig and Fixture Design

Avoiding Over-Constraint and Material Stress

Over-constraining a workpiece can introduce internal stress, causing parts to shift or distort once unclamped. Effective fixture design balances restraint and freedom, stabilizing the part without deformation. Limiting unnecessary contact points prevents stress-related errors and ensures repeatable results.

Designing for Operator Usability

Fixtures must be functional and easy to use on the shop floor. Ergonomic loading, simple clamping, and clear orientation indicators reduce fatigue and mistakes. Practical jig and fixture design devices translate theoretical precision into real-world productivity gains, improving workflow efficiency and operator safety.

Best Practices for Durable and Reliable Fixtures

Planning for Longevity and Maintenance

Jigs and fixtures are long-term assets that must maintain precision over repeated cycles. Replaceable components, like locating pins and wear surfaces, extend service life, and durable materials resist wear. Regular preventive maintenance preserves fixture performance and ensures consistent machining quality.

Collaboration Between Engineering and Machining Teams

Effective jig and fixture design requires close collaboration between engineers and machinists. Shop-floor feedback provides insights into cutting forces, material behavior, and handling challenges. Continuous iteration and improvement of fixture designs ensure that they are robust, practical, and aligned with real production needs, supporting sustained CNC efficiency.

Benefits of Precision Jig and Fixture Design

-

Ensures dimensional accuracy and repeatability

-

Reduces setup time and operator dependency

-

Improves surface finish and extends tool life

-

Minimizes scrap and rework costs

Features of High-Performance CNC Fixtures

-

Stable locating with precise datum references

-

Balanced clamping without part distortion

-

Efficient tool access and chip evacuation

-

Durable construction with replaceable components

Conclusion

CNC efficiency begins with controlled, precise workholding that eliminates variability and guesswork. Jig and fixture design provides this foundation by stabilizing parts, defining accurate reference points, and enabling repeatable setups. By implementing advanced jig and fixture design devices, manufacturers improve accuracy, productivity, and long-term reliability. Investing in intelligent workholding transforms CNC machining from a reactive process into a streamlined, efficient, and consistent production system, ensuring high-quality outcomes and a competitive edge in precision manufacturing.