You have an image that needs to become thread. It might be a sleek company logo destined for employee polos, or a detailed illustration you hope to see on a custom jacket. The journey from that digital file to a pristine embroidered piece hinges on a single, critical skill: digitizing. This is where professional Embroidery Digitizing Services prove indispensable. Acting as the essential translators between art and machine, these specialists convert your visuals into a language of stitches. For creators and businesses across the United States, these services are the bridge that turns simple logos and breathtakingly complex artwork into tangible, wearable quality.

Introduction: The Invisible Art of Embroidery

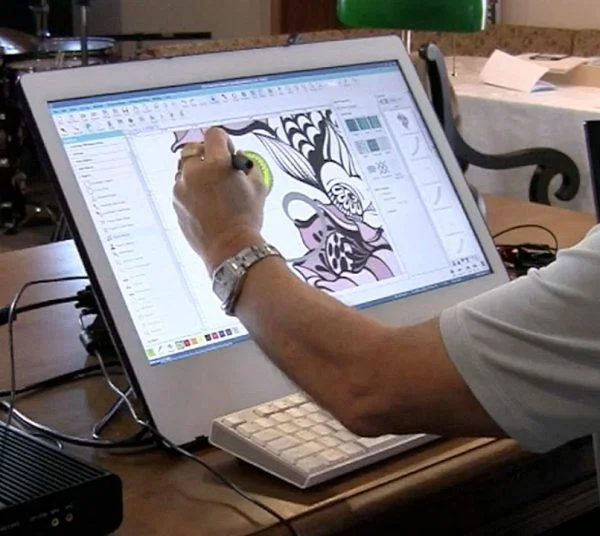

Before an embroidery machine hums to life, a detailed blueprint must be created. Digitizing is the meticulous process of using specialized software to plot the path for every single stitch—dictating its type, direction, length, and sequence. It’s a technical craft that blends graphic design with textile engineering. While software offers “auto-digitize” buttons, these lack the nuanced understanding of fabric behavior and stitch dynamics required for professional results. A skilled digitizer makes countless micro-decisions that determine whether your design lies flat, looks crisp, and stands the test of time. Whether starting with a minimalist logo or a photographer-like image, the right digitizing service is what ensures the final product does your vision justice.

The Spectrum of Work: What Can Be Digitized?

Professional services in the USA handle a vast range of projects, each with unique challenges and requirements.

1. Logo & Branding Digitizing:

This is the backbone of commercial embroidery. The goal here is clarity, reproducibility, and brand integrity.

-

Focus: Clean edges, precise color matching to brand standards, and simplification for legibility at small sizes.

-

Challenges: Converting tiny text into readable satin stitches, managing multi-color logos efficiently, and ensuring the design stitches well on different fabrics (from dress shirts to workwear).

-

The Digitizer’s Role: They strategically simplify gradients and shadows, choose stitch types that make text pop, and build the file for consistent results across thousands of items.

2. Complex Artwork & Illustrative Digitizing:

This is where digitizing becomes an art form itself. Think of detailed portraits, scenic landscapes, or intricate graphic novel art.

-

Focus: Capturing depth, texture, and detail through thread. This involves using stitch density, direction, and special stitch types to mimic shading and form.

-

Challenges: Managing a high stitch count without making the design too stiff, creating the illusion of color blending without endless thread changes, and preserving the emotional impact of the original art.

-

The Digitizer’s Role: They act like a painter, using different stitch “brushes.” They may employ complex fill patterns, layer translucent stitches for shading, and strategically use thread colors to create dimension, all while keeping the file sewable.

3. 3D/Puff Foam Digitizing:

This technique creates a raised, textured effect popular for caps and athletic wear.

-

Focus: Engineering the file to allow for foam insertion under specific stitch areas, typically satin stitches.

-

Challenges: Calculating the precise spacing between stitch columns to allow the foam to expand properly. Too close, and the foam won’t puff; too far, and it will bulge out unevenly.

-

The Digitizer’s Role: They create a separate, offset “tracking” file that guides the machine to stitch the design twice—once to secure the foam, and a final top stitch for finish.

4. Appliqué Digitizing:

Appliqué involves stitching pre-cut fabric pieces onto a garment, then securing and finishing the edges with stitch.

-

Focus: Creating a precise placement stitch, a tack-down stitch, and a final satin or merrow stitch edge.

-

Challenges: Sequencing the steps correctly for the operator and accounting for fabric fray in the digitized edge.

-

The Digitizer’s Role: They create a multi-step file that acts as an intuitive guide for the embroidery machine operator, pausing at the right moments for fabric placement.

Why Source These Services in the USA?

Choosing a digitizing service based in the United States offers tangible advantages that impact quality, communication, and turnaround.

-

Cultural & Market Understanding: American digitizers inherently grasp the style, trends, and quality expectations of the U.S. market, from corporate branding standards to sports team aesthetics.

-

Seamless Communication: Working within the same time zones and without language barriers allows for clear, real-time collaboration. You can easily discuss specifics about fabric, end-use, or desired effects, leading to fewer errors and faster revisions.

-

Rapid Turnaround & Accountability: The proximity enables truly fast turnaround times—often 12 to 24 hours for standard jobs. There is also direct accountability; a U.S.-based service stakes its reputation on your satisfaction.

-

Quality Assurance: There is a consistent expectation of high-quality craftsmanship that meets the standards required by American businesses and consumers. They understand the fabrics and threads commonly used domestically.

-

Intellectual Property Sensitivity: Reputable U.S. services are well-versed in the importance of confidentiality and intellectual property, providing peace of mind when handling your logos and proprietary artwork.

The Expert Digitizing Process: From Your File to Finished Design

Understanding the steps demystifies the service and helps you be an effective partner.

-

Artwork Submission & Consultation: You provide your source file. The digitizer evaluates it, noting potential issues (e.g., too-fine lines) and may suggest optimizations for embroidery. This is the time to specify garment type, size, and any special requests.

-

Strategic Stitch Mapping: The digitizer manually traces and defines each element.

-

They assign Satin Stitches to borders and text for shine and definition.

-

They use Fill Stitches for larger areas, carefully selecting angles to prevent fabric pull.

-

They employ Run Stitches or Complex Fills for details and texture.

-

-

Engineering the Stitch File: This is the technical heart. They add:

-

Underlay: A foundation layer of stitching to stabilize the fabric and prevent puckering.

-

Pull Compensation: Slight adjustments to the shape of elements to counteract the fabric’s natural movement under the needle, ensuring circles stay round.

-

Stitch Sequencing & Trimming: They order the color changes and stitch paths to minimize jumps and thread trims, optimizing production time.

-

-

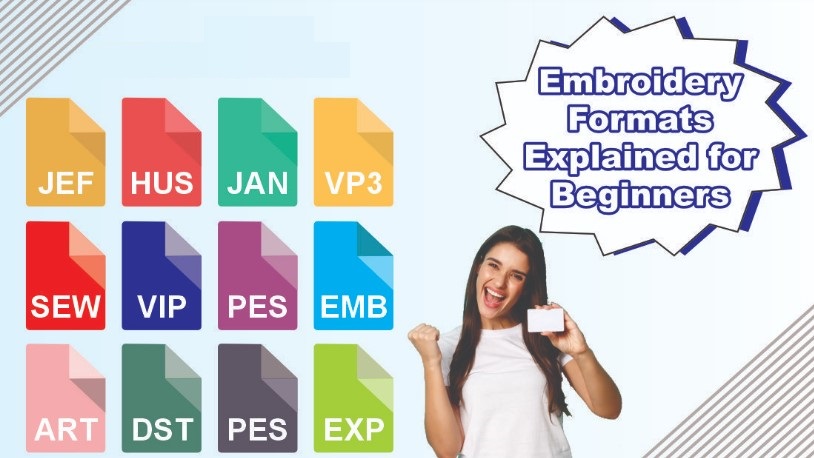

File Delivery & Test Stitch Revision: You receive the machine file (.DST, .PES, etc.). The best practice is to stitch a sample. Professional services typically include 1-2 rounds of minor revisions to adjust density, alignment, or small details based on your test sew-out.

How to Choose the Right Service for Your Project

Not all digitizers excel at all types of work. Use these guidelines to select a partner:

-

For Logos & Branding: Look for a service with a clean, corporate portfolio. They should ask questions about your garment and brand colors. Speed and consistency are key here.

-

For Complex Artwork: Seek out a service that showcases a gallery of illustrative or photographic work. Don’t be afraid to ask if they have experience with your specific style of art. This is a specialty.

-

Check Portfolios Critically: Look for smooth curves, clean satin stitches, and effective use of fill patterns. Beware of designs that look pixelated or poorly defined.

-

Evaluate Communication: Their responsiveness to your initial inquiry is a strong indicator of their customer service approach.

-

Understand Pricing & Policies: Transparent pricing (per stitch count or complexity) and clear revision policies are signs of a professional operation.

The True Value: More Than Just a File

Investing in expert digitizing is investing in the success of your final product. A professionally digitized file:

-

Saves Material and Time: It sews efficiently without breaks, puckering, or reworks.

-

Protects Your Equipment: Clean files reduce wear and tear on your embroidery machine.

-

Elevates Your Brand: Crisp, professional embroidery makes a powerful quality statement.

-

Unlocks Creativity: It allows you to embroider designs you previously thought were impossible.

Conclusion: Your Vision, Masterfully Executed

Whether you’re launching a branded apparel line or creating a one-of-a-kind heirloom, the path from concept to stitch is paved by digitizing expertise. Professional Embroidery Digitizing Services based in the USA offer the technical mastery, collaborative communication, and quality focus necessary to handle the full spectrum—from the clean precision of a corporate logo to the nuanced detail of complex artwork. They provide not just a machine file, but the confidence that your design will translate perfectly into thread. By partnering with the right experts, you ensure that your vision is not just reproduced, but elevated, resulting in embroidered work that is as durable and impactful as it is beautiful.